In today's rapidly advancing world, electrical systems play a crucial role in powering our homes, offices, and industries. Ensuring the safety and efficiency of these systems is paramount to prevent potential hazards such as electrical fires and equipment damage. One essential component that helps maintain electrical safety is the Molded Case Circuit Breaker (MCCB). In this blog, we will delve into the workings of MCCBs, their importance in electrical systems, and how they contribute to keeping our electrical installations safe and secure.

The Basics of Molded Case Circuit Breakers

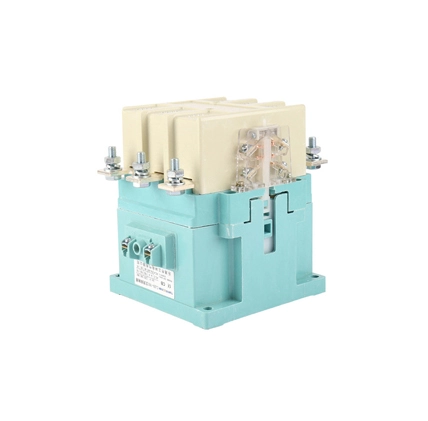

Molded Case Circuit Breakers are protective devices designed to automatically interrupt the flow of electrical current in the event of an overload or short circuit. They are named "molded" due to their thermoset plastic casings, which provide excellent insulation and protection against external elements. MCCBs consist of trip units, arc extinguishing chambers, and mechanical interlocks, all working together to ensure safe and reliable operation.

How MCCBs Prevent Overloads and Short Circuits?

Overloads occur when an excessive amount of electrical current flows through the circuit, exceeding its rated capacity. A short circuit, on the other hand, occurs when two conductors with different potentials come into contact, creating a low-resistance path. MCCBs sense these abnormal conditions and instantly trip, disconnecting the circuit to prevent damage to the equipment and wiring, and reducing the risk of electrical fires.

Types of Trip Units in MCCBs

MCCBs molded case circuit breaker types come with different types of trip units, each catering to specific applications and protection requirements. The most common types include thermal-magnetic trip units, electronic trip units, and microprocessor-based trip units. Thermal-magnetic trip units offer time-delay protection for overloads and instantaneous protection for short circuits, while electronic and microprocessor-based trip units provide more precise and customizable protection settings.

Selective Coordination: Ensuring Proper Protection

In complex electrical systems with multiple circuits and equipment, selective coordination is crucial. It involves configuring MCCBs to trip in a coordinated sequence, ensuring that only the faulted circuit is isolated while leaving other unaffected circuits operational. This selective coordination minimizes downtime and allows faster fault detection and restoration, improving the overall reliability of the electrical system.

Remote Monitoring and Communication Capabilities

Modern MCCBs are equipped with advanced features like remote monitoring and communication capabilities. These features allow facility managers and maintenance personnel to monitor MCCB status, analyze electrical system performance, and detect potential issues remotely. Such capabilities contribute to predictive maintenance, minimizing downtime, and ensuring uninterrupted operation.

Advancements in MCCB Technology

Over the years, MCCB technology has seen significant advancements. Manufacturers are integrating smart features, such as embedded sensors, IoT connectivity, and self-diagnostic capabilities, into MCCBs. These smart MCCBs enable real-time data collection, predictive analysis, and remote control, empowering users to make informed decisions and optimize electrical system performance.

Ensuring Proper Installation and Maintenance

The effectiveness of MCCBs in safeguarding electrical systems heavily relies on proper installation and regular maintenance. Qualified electricians should correctly size and install MCCBs according to the specific requirements of the electrical system. Additionally, periodic inspections and maintenance checks are essential to ensure that MCCBs are functioning correctly and adhering to safety standards.

Molded Case Circuit Breakers are indispensable components of modern electrical systems, providing critical protection against overloads and short circuits. Understanding their working principles, types, and advanced features empowers users to make informed choices in selecting the right MCCBs for their applications. By investing in high-quality MCCBs, adhering to proper installation practices, and conducting regular maintenance, we can ensure the safety, reliability, and efficiency of our electrical systems, contributing to a safer and more sustainable future.